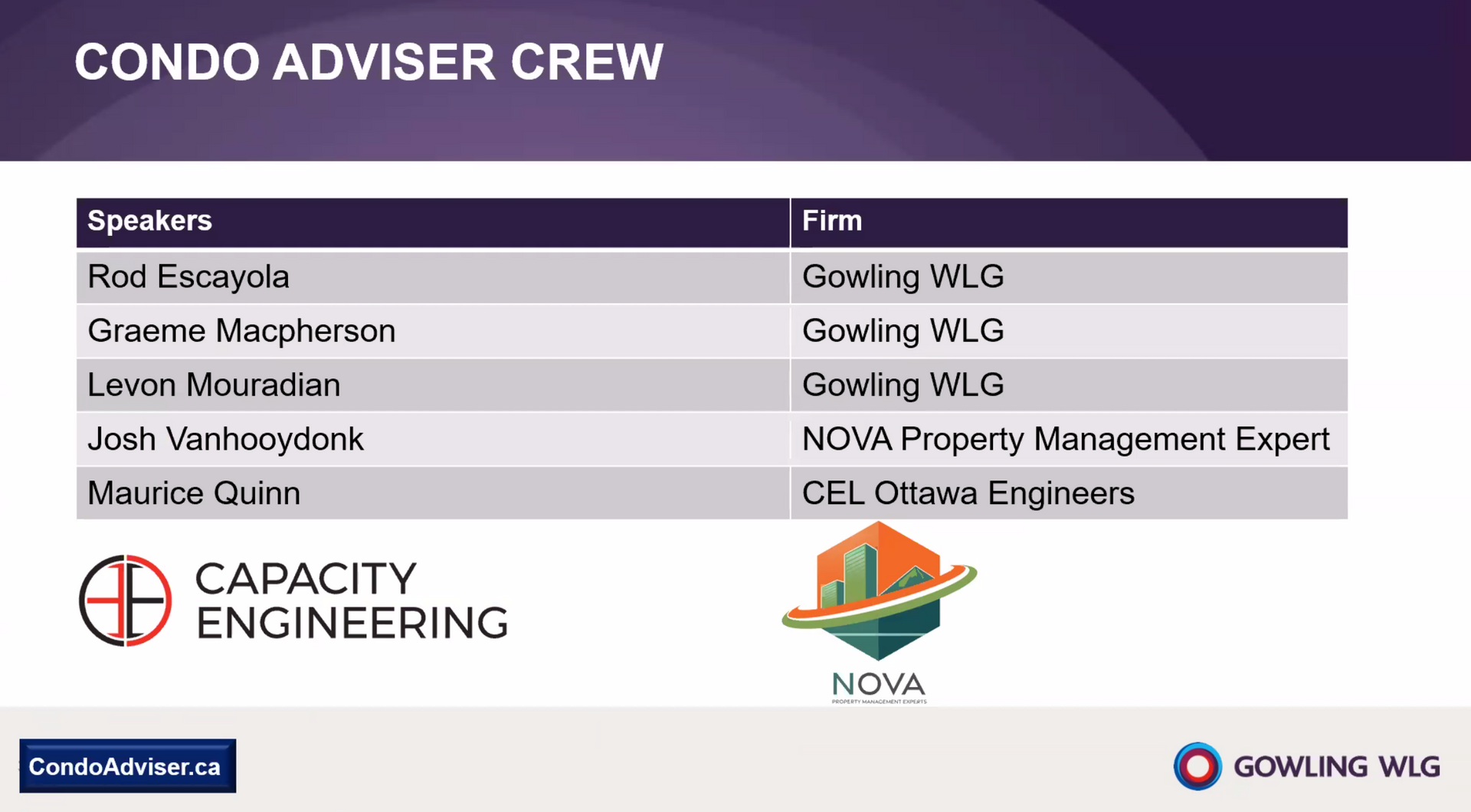

30 Facts in Planning, Design, Permitting, and Construction

30 Frequently Misunderstood (But Routine!) Facts in Construction

We recently had a project start, and stop, restart, stop again, and restart for a third time… All in one morning. So, despite all our steps and checks, care and attention, something key went wrong. In this case, it was communication. A simple miscommunication before a long weekend meant that the entire project exploded. Proverbially, of course; while we do Blast Engineering and Civil Defense work here at CEL, this time we’re looking at metaphors and human factors, not explosives and incidents. I wanted to take the lessons learned and leverage the experience into an internal training memo, refine our CEL PocketPM Project Management Manual, and (hopefully you’ve caught on by now), post something useful to our Blog…

You’ll find a lot of numbered lists in Construction that focus on soft skills and Project Management. These are important, and PM work is key to project delivery excellence, but most PM problems and soft skills can be pushed through, overcome during the project, or pushed away / ignored / banished by the judicious application of time, money, effort, or influence. There are, however, things that no amount of charm or cash will clear out of your way. Let’s discuss the Hard Skills; the things that need to meet with the approval of reality, applicable law and regulation, or simply the timelines that are so lengthy you are effectively dead in the water if you find yourself engaged in a project that forgot those key steps.

The reality of Construction is that the skills required to undertake the work are so varied and diverse that there is essentially no one who knows all the little steps. Like the truism “no one knows how to make a pencil”, there is a level of technological advancement after which knowing all the steps becomes impractical. The people in the pencil factory don’t know how to cut, prep, age, and care for the wood; they could not mine for the graphite safely if they needed to in order to save their lives; they cannot create or provide the paints they use, the rubber they rely upon, or any of a thousand other inputs from replacement parts to electricity. In construction, there are tens of thousands of near silent notes to the orchestra that is a completed project, from how to swing a hammer such that you may do this safely all day, every day, right down through to how long a team can work before they need a break.

The following items respect the truth that there is an unwritten bulk of knowledge, and tries to capture some of these little unmentioned pearls of wisdom and knowledge from the point of view of the Professional Engineers and Project Managers involved in Construction. The list is intended to emphasize the hard skills and avoid the soft. You will find the like of material testing, key milestones, permitting requirements, bylaws, regulations, and common pitfalls that lead to long delays and even project cancellations, but often go unmentioned because they are inherent to the process. You learn them by watching, by helping, and by doing. Our firm calls this the See One, Assist One, Do One training process. Hopefully you may be able to learn a little of our challenges by reading this list and by watching us successfully deliver a project which will be an effective answer for your needs.

Most of all, this is our effort to warn you about the silent project killers. These are the problems that may get forgotten, and have the power to get a project stopped dead in the water.

1. Shop drawings are required to demonstrate a contractor's understanding of design intent but do not universally need a professional engineer's seal; only those involving new engineering designs (e.g., concrete formwork or steel connections) require it, while mere reflections of existing designs with measurements do not, avoiding unnecessary delays.

2. Building codes establish minimum requirements for structural integrity, materials, and safety in construction, but they are not static; local jurisdictions enforce provincially regulated codes (often, for our office, the 2024 Ontario Building Code), however the interpretation and application are very much the purview of the local AHJ (Authority Having Jurisdiction). That means designs need to know the local authorities in order to be successful, leading to project-specific variations that can cause compliance failures and significant delays if overlooked.

3. Construction permits are mandatory for most projects and involve multiple stages, including zoning approval and environmental assessments; failing to secure them early can halt work entirely, as they act as legal gatekeepers enforced by building officials.

4. Noise bylaws typically restrict construction activities to daytime hours (e.g., 7 a.m. to 7 p.m. weekdays), requiring exemption permits for night work; violations can result in fines or stop-work orders, often underestimated as a cancellation risk.

5. Material testing is a regulatory obligation under standards like CSA A23.1, ASTM and CCLI, involving lab verification of properties like compressive strength; non-compliant materials must be rejected or reworked, potentially delaying projects by weeks. If the testing agencies haven’t been arranged in advance, the samples, curing, and testing requirements could easily cause your pour (or other work) to be delayed. A cancelled concrete truck can be a quick additional $3k to $15k. A last minute cancellation of a concrete with nowhere else to go is going to get very expensive, very quickly.

6. Unforeseen site conditions, such as soil instability, are a leading cause of delays. No matter how detailed a geotechnical investigation, things can be missed. Contracts often require geotechnical investigations upfront, while project teams have been known to gamble by skipping them. Both bad luck in missing hidden issues as well as the pure ignorance (triple entendre) of not undertaking reasonable geotechnical exploration, can all lead to costly redesigns or cancellations, or even problematic results and structures which shift and fail with differential settlement or slip-cup failure. Just because you cannot see the geotechnical considerations does not mean those geotechnical conditions are going to remain invisible. A structure built on poor or sensitive soils is likely going to show you some very serious consequences.

7. Planning permission (or zoning approval) must precede construction and permitting, and may involve public hearings; misalignment with land-use regulations can necessitate variances processes, can void permits if caught late (yes; their mistake, your consequences), acting as an early, middle, and late gatekeeper that can and does see the cancellation of non-compliant projects.

8. Occupational Health and Safety Act (OHSA) mandate specific safety protocols, like fall protection and hazard assessments; non-compliance can trigger inspections and shutdowns, often misunderstood as optional rather than enforceable laws.

9. Stage gates in project delivery are formal milestones (e.g., feasibility to procurement) where stakeholders review progress; failing a gate due to incomplete documentation can pause or cancel funding.

10. Environmental regulations under laws like Environmental Assessment Act (EAA; currently R.S.O. 1990, c. E.18) require impact assessments for large projects; overlooking them can lead to legal challenges from agencies or communities, resulting in indefinite delays. Don't forget that waterways have their own Authorities Having Jurisdiction. Congratulations, meet your new friends at the XX YY ZZ Conservation Authority. Honestly; they do great work. Unfortunately, that work may well include telling you 'No', and meaning it forever, regardless of resources (pun intended) you burn trying to convince them otherwise. Like all AHJs, engage early, listen often, make their path of least resistance the approval of your project. You'll thank us later.

11. Design changes mid-project, often from owner requests, trigger delays, may trigger re-permitting, and can necessitate more testing. These are excusable delays when documented properly, and negotiated appropriately; otherwise contractors and consultants may bear the cost. Favours are fine, but contract terms bind.

12. Concrete curing requires specific testing (e.g., slump and cylinder tests) per CAN/CSA standards (A23.1, A23.2, etc.); rushing this milestone without verification can compromise structural integrity and invite regulatory rejections.

13. Labour laws under Employment Standards Act, 2000 (ESA; currently S.O. 2000, c. 41) apply to construction, requiring overtime pay and safety training; violations can lead to Ministry of Labour, Immigration, Training and Skills Development (new abbreviation not as good as old abbraviation, let's just keep 'MOL') audits and project halts, underestimated as a technical gatekeeper.

14. Utility coordination is a key milestone before excavation; failing to mark lines per regulations like Ontario One Call can cause accidents and mandatory shutdowns. Or accidents. See MOL. Do not get this one wrong, whatever you do, always call before you dig.

15. Fire code compliance, including material flammability tests, is enforced during inspections; non-passing elements can delay occupancy permits, a common late-stage cancellation trigger.

16. Supply chain regulations, like Accessibility for Ontarians with Disabilities Act (AODA), mandate material sourcing; ignoring them can invalidate contracts and force rework.

17. Structural load testing is required for certain elements (e.g., bridges) under Ontario Provincial Standard Specifications (OPSS), Ontario Provincial Standard Drawings, and the Canadian Highway Bridge Design Code (CSA S6); skipping or failing tests can lead to engineering board interventions and project scrapping.

18. Wetlands permits from agencies like the Ministry of the Environment, Conservation and Parks (MECP) are gatekeepers for site development; unauthorized disturbance can result in fines exceeding project costs and forced restoration. Remember our friends at the XX YY ZZ Conservation Authority? Yeah; insert them here again.

19. As-built drawings must document deviations from plans; inaccuracies can violate certification requirements, blocking final approvals.

20. Seismic design codes vary by region and require engineering calculations; underestimating risks can fail plan reviews, delaying starts. Ottawa and the surrounding areas are a seismic zone, and the detailing of load paths, complete with proper stiffness and strength, is not at all optional. It is not pixie dust, and the idea that a seismic event is Neverland (ie: never, never, going to land on a day that matters to us) is a wholly unacceptable dodge of professional responsibility suitable only for rebuke.

21. Erosion control plans are mandated by stormwater regulations; non-compliance during construction can lead to stop-work orders. Keep those Conservation Authorities in mind. Talk to them; don't guess, or hope to be forgiven.

22. Welding inspections per Canadian Welding Bureau standards (CSA W47.1 and W59) are routine for steel structures; defects found late can require demolition and rebuilds.

23. Accessibility regulations under Accessibility for Ontarians with Disabilities Act (AODA) demand specific designs (e.g., ramp slopes); retrofits for non-compliance post-construction inflate costs.

24. Commissioning of systems (e.g., Electrical, HVAC) is a quite important. The testing of integrated systems under CAN/ULC-S1001 'Integrated Systems Testing of Fire Protection and Life Safety Systems and Fire Protection Commissioning' is now becoming mandatory and enforced by AHJs prior to occupancy; incomplete testing, or issues revealed during testing, delays occupancy and may rather swiftly balloon costs.

25. Hazardous material handling laws (e.g., asbestos abatement) require certified procedures; mishandling can trigger health department closures.

26. Bond and insurance requirements are gatekeepers for public projects, particularly public projects; insufficient coverage can disqualify bids and cancel awards.

27. Soil compaction testing is essential per geotechnical standards; poor results can undermine foundations, leading to settlements and claims. The proper compaction of sub-grade as well as Hot Mix Asphalt (HMA) is key as well. Testing is wise, and skimping on recommended testing is penny wise, but pound foolish. Ensuring a good quality product is placed and compacted to 98% Standard Proctor, 100% Modified Proctor, or at least 92% Theoretical Maximum Density (for HMA; 95% to 98% are excellent and more normal for 'SuperPave') is simply impossible without testing, and truly key to performance and durability.

28. Utility easements must be cleared before groundbreaking; encroachments can invoke legal disputes and project halts. This is particularly true, and important, for distribution and supply electrical lines. The requirements for local eletrical companies differ one from the other, and differ from the provincial requirements as well. They are not known for breaching their rules. We have seen buildings torn down, reconstructed, or subject to major changes in design and scope due to the incorrect encroachment rules being applied during construction. This is a planning step you want to get right without fail.

29. The code has a lot of speciality compliance issues as well. Energy code compliance (Supplementary Bulletin 10, 'Energy Efficiency Requirements [SB-10]) involves performance testing; failing efficiency benchmarks can require redesigns late in delivery. Issues with glass safety in tall structures has led to Supplementary Bulletin 13 'Glass in Guards'. Essentially, if there is a Supplementary Bulletin, you really want to make sure your project is in compliance. The SBs have been added to address key issues. There are also mandatory testing and compliance standards referenced by the code that must be respected. All fenestration products, windows and skylights, etc., must be selected and tested in accordance with the North American Fenestration Standard (NAFS). NAFS is just another stepping stone to your compliant project, and yet another area that can stop your project dead in its tracks.

30. Final inspections by building officials are the ultimate gatekeeper; unresolved punch list items can prevent certificates of occupancy, effectively cancelling handover. Remember our Commissioining and Integrated Systems Testing. Time to have the Architect of Record and all Engineer(s) of Record sign-off documentation ready.

There is no magic to a 30 item list, in fact we really had to think to get more than 27... There does, however, seem to be some magic in grabbing attention, and getting people to read the posts. If three duds gets this information in front or more people in the construction industry, well, that's a win. The truth is this is an industry with plenty of known unknowns and "silent project killers" which can derail even the most meticulously planned projects. The deadliest enemy of all is lack of, or mis-, communication.

Like most situations, increased work and putting your shoulder to the millstone is the best potential way out. The lesson we want you to learn from our chaotic morning of starts and stops is this: Don't Panic. There is always a solution; work the problem, not the panic. Work with the people, loop everyone in, measure and value the risks. Educate, and overcome.

These 30 hard-skill facts, from permitting pitfalls to material testing mandates, highlight the non-negotiable realities that demand attention early and often. By understanding and addressing these routine yet frequently misunderstood elements, you can avoid costly delays, redesigns, or cancellations. At CEL, we leverage our "See One, Assist One, Do One" approach to navigate these challenges, ensuring projects stay on track. Have questions or need guidance to sidestep these traps? Please feel free to reach out to us for help, or even to share your own experiences; we’re here to help build success.