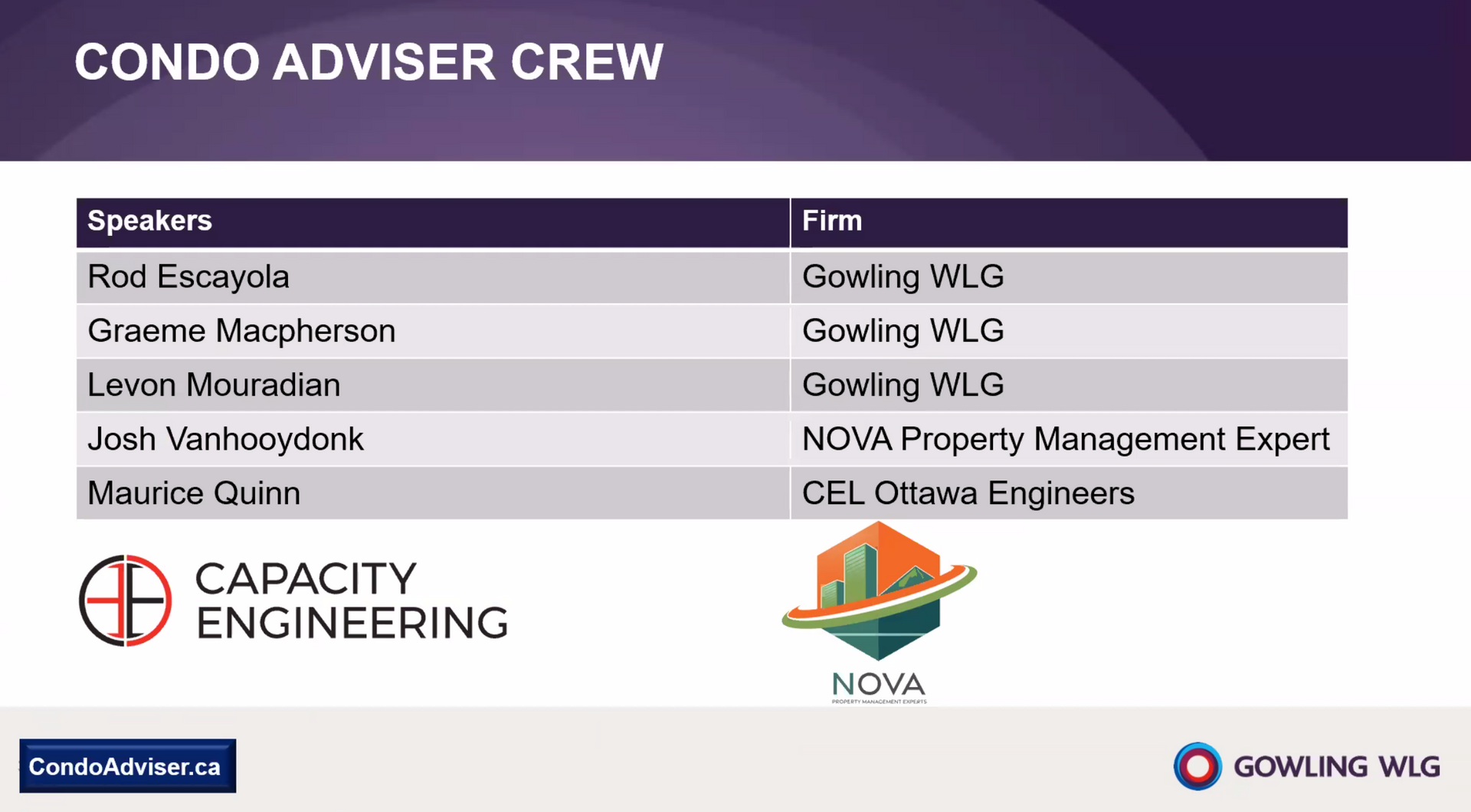

Fastening Matters: The fix is in.

Fastening Matters: The fix is in.

We see a lot of connections in our work. Not all of these work well, or are what they should have been, particularly existing conditions that never met any kind of engineering or manufacturer specification. While we see some connections that are entirely incorrect, most often these connections are well built poor performers. The person putting them together made common errors, didn’t understand the connection, and/or the oversight was simply deficient. Let’s discuss some common errors, after which we’ll offer some handy tips.

Hanger Nails are Hazards

Most of the time, a contractor installing a timber joist hanger simply fills all the holes with Hanger Nails. Why not? They are for hangers, right? Well yes, and no…

So called “Hanger Nails” are short (1 1/2”) specialty fasteners needed for rare issues and the occasional specified location. They should not be your go to nail. When you install them in a hanger, you get a lower strength than if you’d saved yourself the money and put in a common, and “Hanger Nails” can never be used in a toe nail position, even if through a hanger. Take a look here for more details: https://www.strongtie.com/products/connectors/wood-construction-connectors/technical-notes/fastener-types-and-sizes

Here’s a great post in a home inspector’s blog discussing this in detail: https://www.constructionprotips.com/departments/home-inspector-tales/how-to-correct-improper-joist-hanger-nails/

Screwed Up

We see a lot of hangers with regular screws, drywall screws, or deck screws. There is a reason the typical screw is called a “machine” screw. They aren’t for buildings, and they certainly are not for timber hangers. If you’re connecting wood to wood, the right fastener is a nail. Screws are for decks, or are specialty products that you don’t need to build a normal structure. Once in a while, a specialty timber connector requires screws; take a look at those screws sometime: They are a very special design, with large shanks and not at all like a machine screw. Don’t use them unless you have the need to do so in writing.

Not all bolts are equal

Structural bolts are black, heavy hex, bolts. They have heads far larger than you are used to seeing, or are special fasteners made for wood applications like Coach Bolts and Lag Bolts. Coach and Lags are A307 bolts and nearly always come with a Hot Dip Galvanized coating. They are exclusively for wood, often without any steel involved.

So what do you use when there is steel involved? Sadly, most of the time, the same bolts that go on cars and trailers get used. They aren’t up to the job, and are unsafe. The steel material specs are nearly the same, but everything else is meant for an easily accessible, visually inspectable, short term service use. A bolt in a car or trailer may have to last ten years of constant use. A bolt in a building may have to serve 50, 80, more than 100 years. They are not equal challenges, and material engineers treat them differently.

We very commonly see bolts on site that don’t meet the requirements of the code. This isn’t a minor issue, but it is easily avoided with a little knowledge. If your bolt is “bright”, you’re being dim. We’re unaware of any structural bolt available with the common bright zinc coating. If your bolt has a shimmer, or a head that accepts a wrench and isn’t much thicker than the wrench, it is the wrong bolt until proven otherwise. We’ll put our money where our internet mouths are: Call our team, show us the bolt and the proof, and lunch is on us.

Tips and Tricks:

- Nail it.

The standard nail in use is the “Common”. You also see a lot of Ardox (twisted along the length). Both of these nails are well made, quality products, mass produced and easily found for good prices. Use them. When in doubt, use a common. If you’re outside, you a Hot Dip Galvanized common nail. You rarely need anything more, and if the nail is longer than the piece into which you’re driving, clinch the nail on the back. Most of the time, it is as simple as using a common nail.

- Don’t screw up.

Unless you’re looking at a specification that calls for screws, don’t use screws. Even specialty screws can be hard to get right and confusing for all but the most experienced designers and knowledgeable contractors. If you don’t have someone running the numbers, then run from the screws.

- Bolt with Caution.

When you have steel on your project, have the fabricator apply your nailers (timber bolted to the beam in order to accept nails on site) and prepare you a kit with the fasteners you need. The shop will have easy access to the right heavy hex bolts, and the price you pay will likely be little different than running around for the parts… Besides; We’ve seen shops throw in the bolts for free to attract you back. Let them help you; lean on your fabricator friends.

We’re going to leave you with a little visual hint as to what happens when you get fastenings wrong. This one happens to be what happens when you install an SAE 325 bolt instead of a proper structural heavy hex bolt (ASTM A325).